As COVID-19 government restrictions went in place across Washington and many hospitals became overwhelmed with patients, Renton Prep ninth-grader Alden Johnson thought of a way he could help. With a 3D printer and printing materials, Johnson found that he could make face shields and send them to local hospitals to help.

At 40 minutes each to produce, Johnson was able to package dozens of shields and ship them to places that need them most. He adapted his process quickly to cut production time in half and send out more face shields.

We asked Johnson a few questions about his 3D printing and how he created the shields.

With the adjustments, we were able to print out 12 in a day on our best day. We quickly realized that if this was going to help hospitals we were going to need to get them out to them ASAP. Once supply for the masks and face shields starts speeding up from companies that specialize in making medical equipment, the hospitals would have no more need for our face shields.

Who supported you in developing the design/specifications?

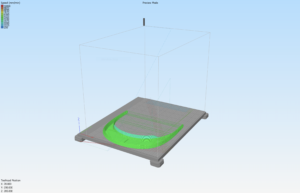

Who supported you in developing the design/specifications?Johnson: I did not personally design it as I knew that masks designed specifically for the task of mass manufacturing masks for healthcare workers would be much better. [The mass-manufactured design] checks off all the boxes required by healthcare professionals.

The hospitals we donated to are Harbor View Hospital, Valley Medical Center, and Swedish Hospital. We also donated to The Sophia Way homeless shelter as they are not going to be able to get the supplies as fast as hospitals.

Renton Prep Christian School provides a great environment for students to learn what it truly means to be an initiator. We are proud of our technology-based education that gives students the resources to improve our future. Our students learn skills that will follow them in the workforce and beyond.

Contact us today to learn more about how we integrate technology into our education.